Why Spreadsheets are too Complicated for Spare Parts Management

Most OEM rely on spreadsheets to manage spare parts inventory and order fulfillment. While this approach may work for small manufacturing businesses with limited SKUs, it can quickly become unmanageable as the spare parts catalog expands.

Managing large volumes of spare parts data in a spreadsheet can lead to inefficiencies, errors, and miscommunication between departments. These issues often result in delays, incorrect orders, and customer dissatisfaction, ultimately damaging brand loyalty.

Operating in a growing $11.76 billion spare parts market requires precision, agility, and data-driven decision-making. This article explores the pitfalls of using spreadsheets and highlights how modern tools like Partable can transform spare parts management into a streamlined, revenue-driving function.

The Hidden Costs of Spreadsheet-Based Spare Parts Management

1.) The Complexity Trap

Spreadsheets are often the default choice for businesses because of the familiarity and flexibility. One significant benefit of a spreadsheet is its ability to organize quantitative data for quick evaluation. However, when a spreadsheet is used as a large data repository, it can become complicated. Aftermarket specialists spend excessive time reconciling spreadsheets, and incorporating vendor or distributor data adds further complexity. The risk of human error can increase dramatically, like

- SKUs can be duplicated or miscategorized

- Manual updates create data inconsistencies

- Multiple versions of spreadsheets lead to confusion

Pro tip:

CDS Partable uses AI to extract spare parts data from CAD files and accurately maps it to the correct components. It integrates with legacy systems like PLM and ERP platforms, ensuring real-time updates across all departments. Building a single source of data ensures visibility and collaboration work better.

2.) Manual and inefficient spare parts ordering processes

When manufacturing equipment fails, speed is crucial. This is because, when manufacturing equipment breaks down, the last resort lies with the OEM. Over the years, enhancements and modernizations have been made to manufacturing equipment. For spare parts departments managing spare parts data through a spreadsheet, each replacement part search requires looking at multiple systems, leading to further delays and customer frustration.

Pro tip:

Leverage advanced search functionality like serial number search, image search, and AI-powered image search to empower your site visitors to easily locate the replacement parts they need on your sales portal or eCommerce site.

Additional resource:

FREE EBOOK: 6 Steps to Streamline Spare Parts Management that Boosts Profits

3.) High cost associated with spare parts management

Holding spare parts inventory can be costly and inefficient. While spreadsheets can assist you with forecasting based on stale data, they lack the real-time data on what is in demand. These setbacks limit the type of promotions and upselling options that can be imposed to sell more spare parts. Moreover, holding a large amount of spare parts inventory means that working capital is tied up.

Pro tip:

Experience higher sales volume with accurate and efficient, always-on, self-service checkout. Empower vendors and in-house technicians with tools to confidently search for, find, and buy parts on your site.

4.) Limited customer service options

Running a spare parts department with a spreadsheet limits you to the type of service options you can offer your customers. As versatile as spreadsheets are for data management and analysis, they fall short of providing a truly digital experience for customers. This results in numerous inefficiencies in the procurement of spare parts for customers.

Spare parts digitization holds an immense promise for enhancing the after-sales experience, but OEMs should remember that customer satisfaction is built by streamlining the fundamentals. The latest digital tools will not sway customers who still struggle to procure the correct part quickly and easily.

Pro tip:

Empower customers with self-service tools like intuitive part identification, live inventory visibility, and easy ordering. This can build loyalty and minimize service cycle friction.

5.) Limited revenue growth

Relying on a spreadsheet can stifle innovation and scalability. It prevents spare parts teams from leveraging

- Automated order fulfillment to accurately sell spare parts to customers without the back-and-forth to ensure that the right spare parts are procured.

- Real-time product lifecycle updates to understand the level of demand

Digital transformation unlocks new revenue opportunities and strengthens margins by enhancing operational efficiency and fostering better customer engagement.

Pro tip:

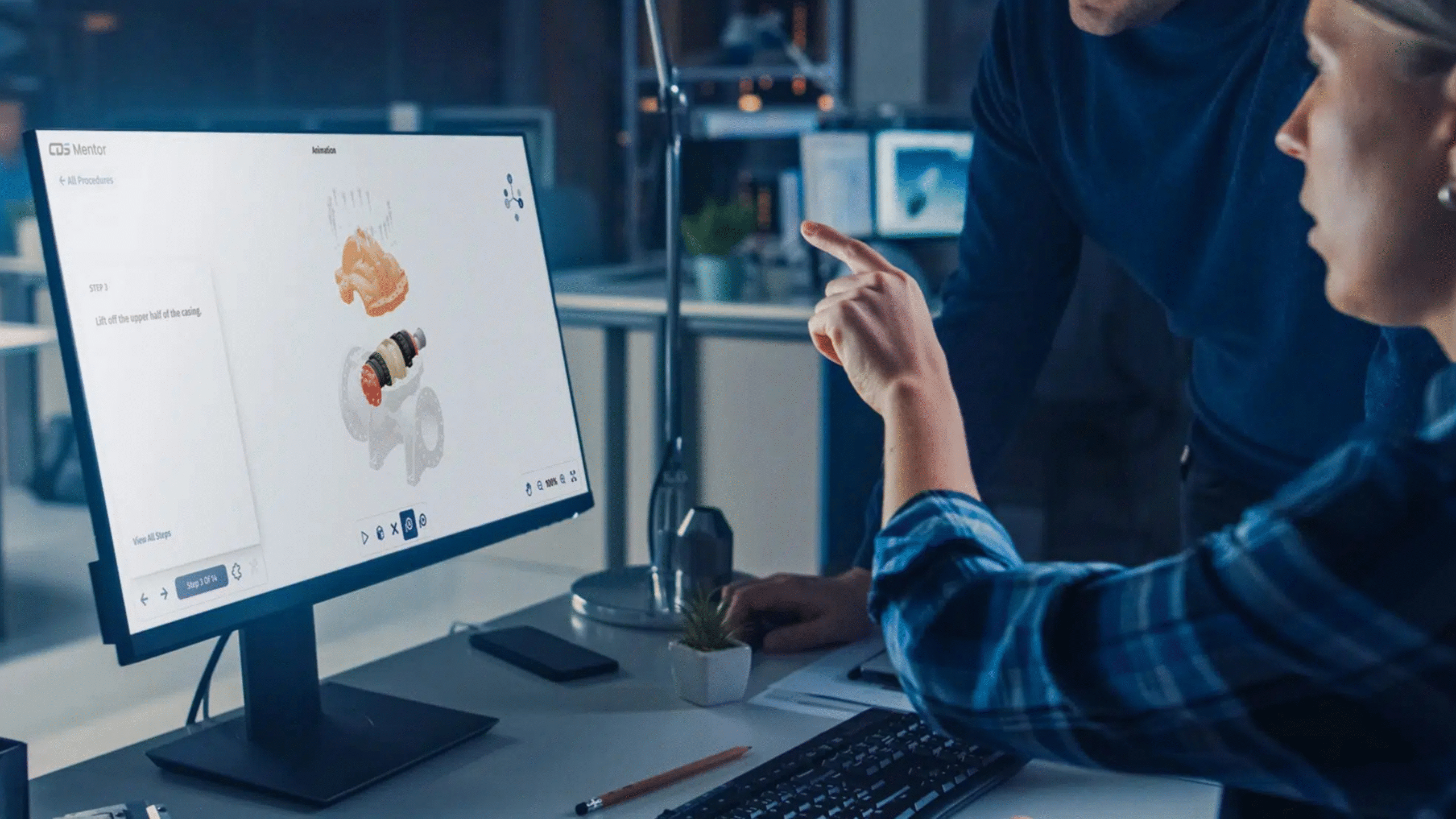

Sell more complex parts using 3D exploded views to control the level of explosions for your 3D models. This empowers you to decide on what spare parts to showcase to your ideal customer.

How can digitizing spare parts management accelerate growth and efficiency?

Digital transformation in spare parts management has the potential to profoundly benefit OEM businesses, end customers, vendors, and corporate margins. It can enhance customer interaction with brands and eliminate frustrations during the search, discovery, and purchasing process. Additionally, it can provide revenue-generating opportunities such as cross-selling and upselling. In times of economic uncertainty, agility and flexibility are a winning strategy for staying above turbulence.

Why Partable is the Better Choice

With Partable, OEMs can move beyond static spreadsheets and into a dynamic, data-driven future. Its intelligent features enable:

- Duplicate detection to eliminate inventory waste

- Live updates on part availability and discontinuation

- Enable serial number searches, image search of spare parts, and AI-powered image search

Proven Results with Partable

- 37% increase in spare parts sales

- 85% reduced time spent on troubleshooting customer issues

- 53% increase in cost savings due to error reduction in order fulfillment

- 35% increase in additional sale promos and bundles

Spreadsheets may be a familiar tool, but they aren’t built for the complexity and speed required in modern spare parts management. By upgrading to intelligent tools like Partable, OEMs can reduce costs, boost revenue, and deliver the seamless digital experience customer’s demand.

Do you want to see Partable in action? Request a demo today!

Back to Blog