Can Visual 3D Hotspots Revolutionize OEM Genuine Parts Businesses?

Original equipment manufacturers (OEMs) with after-sales genuine parts and services businesses are observing firsthand how much the landscape has shifted. Leaders in their respective industries have recognized the potential of their parts businesses to contribute sustainable and profitable revenue to the organization. However, cumbersome and non-standard parts procurement processes leave spare parts management and maintenance disconnected from the core business. At the same time, they lacked the appropriate tools to view parts data in real-time, which prevents users from accurately identifying and securing the parts they needed.

Customers, whether they’re seasoned technicians or end-users, demand the instant feedback and pinpoint accuracy they experience in their B2C online shopping experiences. If OEMs are not constantly innovating their after-sales customer experience, they risk losing ground to aftermarket competitors that make the replacement part process easier. When customers opt for aftermarket parts, they risk compromising their brand reputation and loyalty. A major goal of your genuine parts business should be to safeguard brand loyalty, ensure equipment uptime, and secure long-term revenue.

Many category leaders are convinced that the digital transformation of the genuine parts procurement process is essential to long-term growth and sustainability. They are focused on implementing a digital parts catalog with visual 3D hotspots to facilitate fast and easy part identification across all channels.

What Are Visual 3D Hotspots, and Why Are They Essential to Your Genuine Parts Business?

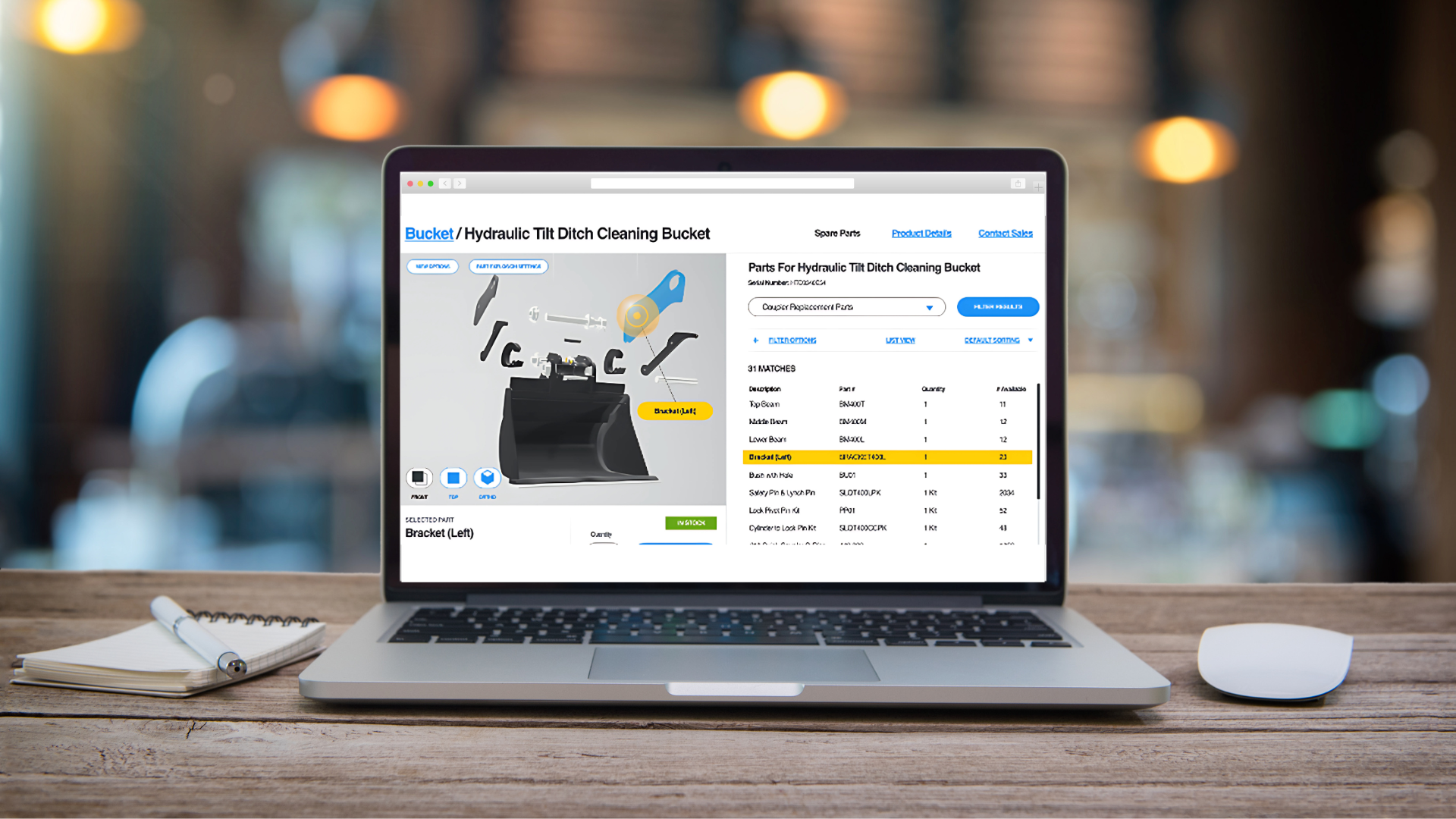

Visual 3D hotspots are interactive points embedded directly into a realistic digital model of equipment or its sub-assemblies. Imagine zooming into a complex machine model and having the ability to navigate down to every part assembly or part, rotating it to see every angle, and then simply clicking on it to instantly reveal its part number, description, price, availability, and potentially even installation instructions.

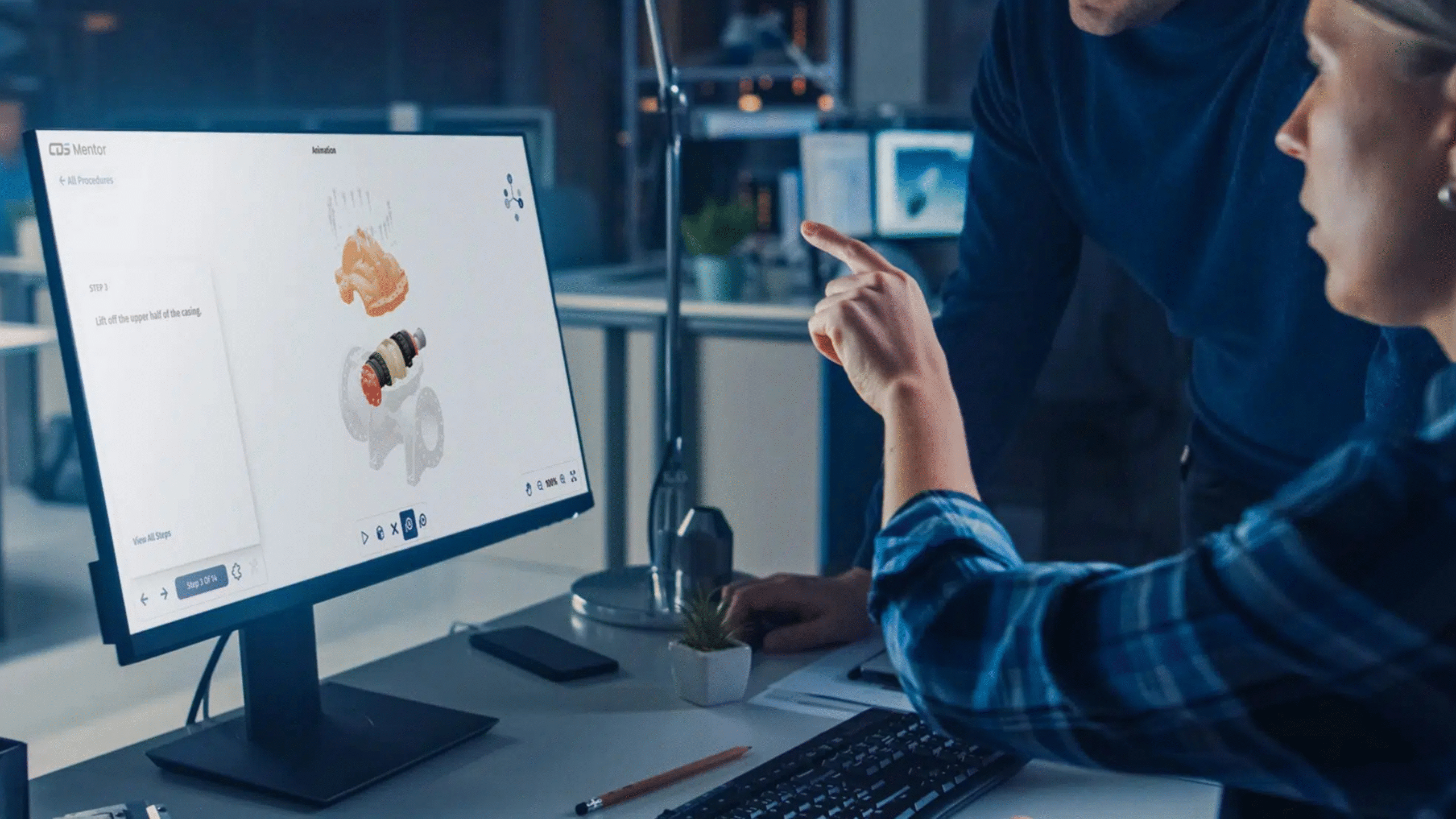

Interactive visualizations represent a game-changing advancement over static 2D images, PDF catalogs, or endless lists of part numbers, which turn part identification into a tedious and time-consuming task. Flat visuals and drawings typically still require an extensive technical understanding to decipher, whereas 3D visual hotspots provide an intuitive and immersive experience that seamlessly guides customers from parts identification to purchase.

When CAD assets power 3D visualizations, you gain the opportunity to represent assemblies and components realistically. By providing customers with accurate visual 3D hotspots, you empower anyone from a seasoned technician to a customer with a minimal technical background to navigate and compare the digital model with physical reality.

Providing users with the ability to interact with the product visually is precisely what makes 3D hotspots an indispensable tool for any OEM committed to boosting genuine parts sales and reducing costs associated with the procurement process. They eliminate ambiguity and drastically reduce the potential for misidentification and the subsequent costs of returns and reprocessing.

What are the Key Types of Visual 3D Hotspot Use Cases?

The versatility of visual 3D hotspots extends across various applications that are designed to maximize efficiency and customer satisfaction in your genuine part sales processes. Each type serves a unique purpose, enabling precise part identification and enhanced understanding within complex machinery. The adaptability ensures maximum efficiency and visual clarity in your genuine parts catalog.

Here are the key types of visual 3D hotspots that OEMs are leveraging to transform their aftermarket operations:

- Exploded Views: Ideal for complex assemblies because they can show how each component fits together in a disassembled state, making individual parts easily distinguishable. An exploded view visually separates components of an assembly, showing each part individually while maintaining its spatial relationship to the whole equipment. For an OEM’s customers and technicians, this means effortlessly identifying even the smallest part within an intricate gearbox, dramatically reducing the potential for misorders and speeding up service.

- Assembly Views (In-Context Selection): Unlike exploded views, assembly views present the components within their fully assembled context. Users can interact directly with the complete machine, clicking on visible parts to access their specific details. Assembly View hotspots are invaluable for understanding how a part functions within its operational environment and for selecting components that might be partially obscured or deeply embedded. It mimics the real-world experience of seeing the machine and identifying the specific elements to ensure an accurate selection every time.

- Interactive Schematics: Beyond physical components, many OEM products rely on intricate electrical, hydraulic, or pneumatic systems. Interactive schematics bring these complex diagrams to life by providing visual 3D hotspots on wires, valves, pumps, sensors, or any other components of the product, allowing technicians to quickly trace circuits, diagnose issues, and pinpoint the exact component needing replacement. These hotspots help streamline diagnostics and minimize downtime by enabling technicians to identify specific elements within a system quickly.

How Visual 3D Hotspots Power Seamless Part Identification and Search

Hotspots are a great tool for drawing a user’s attention to a specific callout or, in the case of a machine assembly, to particular components and parts. The power of visual 3D hotspots lies in their simplicity and the sophisticated integration they enable, helping technicians identify the exact parts they need in order to complete a repair.

Here’s how visual 3D hotspots help streamline the entire parts sales process by making parts identification quick and easy.

- Intuitive Interaction: Users can effortlessly rotate, pan, and zoom into accurate and detailed 3D models of the assemblies. As they explore the product, key components are highlighted to draw the user’s attention to the relevant components. A simple click on a visual 3D hotspot reveals all associated data, including specific part numbers, detailed descriptions, real-time pricing, stock levels, and compatibility information. Hotspots empower users with self-service parts identification, which can drastically reduce the need for timely and costly support calls.

- Direct-to-Order Functionality: The beauty of a well-integrated system is the seamless transition from identification to purchase. Once a part is identified through a 3D hotspot, it can be added directly to a shopping cart or trigger a Request for Quote (RFQ) process within the same intuitive interface, minimizing clicks and accelerating your genuine part sales cycle.

- Real-time Data Integration: Achieving true efficiency requires connecting your 3D visual spare parts catalog with backend systems, such as ERP systems, inventory management systems, or e-commerce solutions. Integrating critical systems that are essential to your parts data ensures that the information displayed is always accurate and up-to-date. Real-time visibility is crucial for making informed purchasing decisions and setting accurate customer expectations.

- Accessibility Across Devices: Modern solutions leverage web standards, such as WebGL, to ensure that interactive 3D models within your digital parts catalog are accessible on any device with a web browser, regardless of the device’s model size. Providing users with anytime, anywhere access ensures that you can support field technicians, support staff, and end customers across all channels.

Meet CDS Partable: the AI-powered Parts Catalog Solution Built for OEMs to Maximize Part Sales

CDS Partable is built to empower OEMs to revolutionize their genuine parts sales experience, improving both the top and bottom lines. Our industry-leading technology platform helps simplify the complexities of OEM after-sales genuine part operations, enabling the seamless transformation of complex engineering CAD designs into intuitive, interactive 3D part catalogs with hotspots, which facilitate easy part identification.

With CDS Partable, OEMs can:

- Automate 3D Catalog Creation: Drastically reduce the manual effort and time traditionally required to build and update parts catalogs.

- Ensure Data Accuracy: Link 3D visuals directly to authoritative Bill of Materials (BOM) and ERP data to eliminate discrepancies.

- Deliver a Superior User Experience: Provide customers and service technicians with an unparalleled visual search and ordering process on any device.

- Gain Actionable Insights: Track part search and order behavior to optimize inventory, identify popular parts, and better understand customer needs.

CDS Partable is committed to providing a robust, scalable, and secure solution that not only streamlines operations but actively drives revenue growth for your genuine parts business.

If you’re interested in a personal consultation, we would love to show you how it works with a demo.

Back to Blog