Industrial Manufacturers are Focused on After-Sales Parts and Services

Efficiency and digitalization are no longer optional for industrial manufacturers, especially within the capital equipment product lifecycle.

In my 20+ years of experience working with industrial manufacturers on their digital transformation and now as General Manager of CDS Visual, I have seen many of the problems up close and personal while also going through the process of developing advanced technologies to solve them. In the last several years, there has been a noticeable focus on after-sales parts and services from our customer base.

Our recent webinar, led by Aaron Smith (VP of Solution Engineering) and Nick Thompson (Head of Marketing & Product Portfolio), explored the transformative potential of digitalizing genuine spare parts processes based on learnings from our customers. You’ll find the key takeaways below. (Feel free to skip the recap and watch the full webinar on demand.)

Why the Digital Shift in Spare Parts Sales has Accelerated

The industrial equipment sector is undergoing a significant transformation. Supply chains face ongoing disruptions, the economy is turbulent, and your customers demand more from their equipment. Consequently, you, as an original equipment manufacturer (OEM), must adapt to these challenges. End customers are keeping equipment in service longer, putting stress on your ability to serve them by making their equipment work more efficiently for longer.

The need for a robust, digitalized spare parts process has never been more critical to meet the customers’ need to keep machine downtime as minimal as possible. Whether it’s through service technicians, end customers, your distribution partners, or through a robust ecommerce offering, making spare parts easy to identify and procure should be a top priority to build stronger relationships, generate revenue, and maximize machine uptime.

While a few of our current customers were highlighted in this webinar, the reality is that the majority of industrial OEMs with a genuine part business rely heavily on that revenue to hit their goals. In our customer base, they typically see anywhere from 15-40% of their annual revenue coming from genuine parts. While many of our customers have expressed that they are losing up to 40% of their potential parts revenue to aftermarket competitors, research indicates that number could be as high as 67% in some industries.

The bottom line is that to strengthen customer relationships, you must support them after sales to maximize equipment uptime and build trust. Digitizing your spare parts procurement process to make it simple and frictionless to procure genuine spare parts is the first step to achieving that goal.

Let’s explore the key takeaways shared by Aaron and Nick from our webinar.

The Digital Parts Advantage: Key Takeaways from our Webinar

Our webinar explored how manufacturers can leverage digital solutions to enhance efficiency, reduce downtime, and ultimately drive sustainable and meaningful revenue from their genuine part business.

Here’s a comprehensive look at the key insights shared during the session.

1.) The Importance of Digitalization to Build Sustainable Growth for your Genuine Parts Business

We off the session by highlighting the growing trend of digitalization in the spare parts industry. With economic turbulence and supply chain challenges, customers are keeping their equipment operational longer, driving overall growth in the spare parts industry. The shift over the last several years underscores the importance of a strong parts and services arm in any OEM with a genuine parts business. Digitalization of your parts procurement processes streamlines operations while also building trust with customers by ensuring the timely and accurate delivery of the parts they need to repair the equipment.

2.) Overcoming Parts Identification Challenges is the Foundation of Digitizing Your Spare Parts Business

The most significant hurdle in spare parts management and sales is parts identification. We emphasized that the universal challenge facing industrial manufacturers is identifying the correct part, especially when part numbers are unknown. If a customer or technician has the exact part number, it’s typically painless to find the part and get it delivered quickly. But in reality, most large industrial equipment works under harsh environments that can cause parts and components to degrade, often eroding any part identification indicator.

Traditional manual processes that require multiple phone calls with layers of technical support just to identify the part are time-consuming and prone to costly errors. Industrial equipment manufacturers are adopting digital solutions to identify parts quickly and accurately, thereby accelerating the procurement process.

3.) Enhancing Customer Experience and Low-Touch Part Sales with Self-Service Portals

The webinar highlighted the shift towards self-service portals that allow customers and partners to perform part searches independently of customer service reps. The approach not only reduces the burden on customer service teams but also empowers customers to resolve issues quickly through self-service options. As we demonstrated, these portals can transform a traditionally manual process into a seamless digital experience that mimics consumer experiences (like Amazon) and is available 24/7. When a machine fails during off-hours, a self-service portal allows end users to purchase the part without waiting until the next business day.

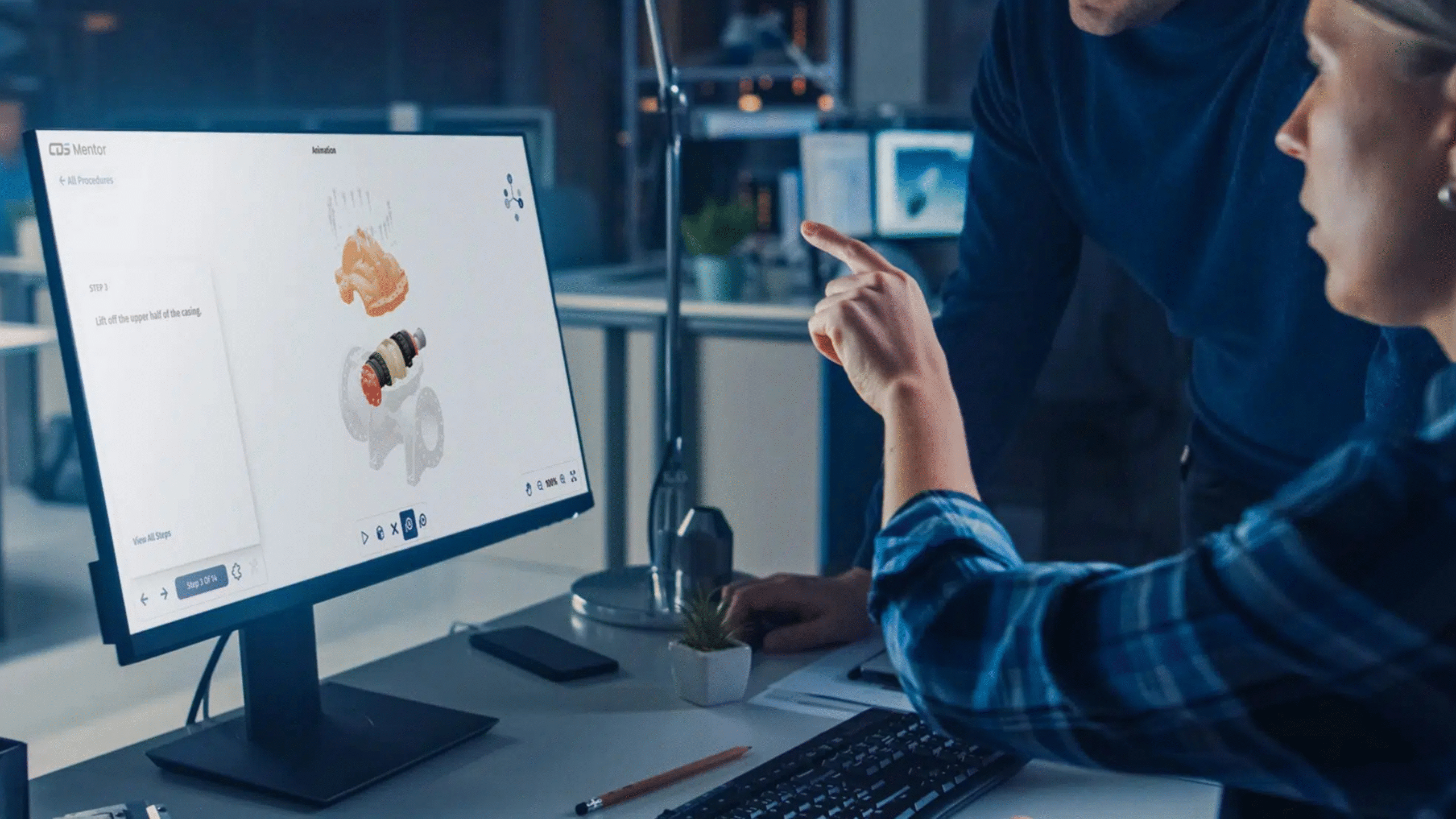

4.) Leveraging 3D Interactive Search Simplifies Parts Identification

A standout feature discussed was the use of 3D interactive part search tools. Utilizing existing CAD assets ensures you have 100% accurate 3D visualizations that engage users with exploded views of their equipment, hotspots calling out specific assemblies and parts, and the ability to inspect a digital twin of the product visually down to the exact part they need. Using CAD models to generate 3D visuals ensures the exact precision users need to visually identify parts for repairs, reducing errors and improving order accuracy.

5.) The Competitive Edge of Digitizing Genuine Part Sales

We emphasized the importance of providing a seamless, genuine spare part purchasing experience that fosters trust with your customers. Your end customers are heavily reliant on machine uptime, and making the parts procurement process simple and fast is a competitive differentiator. If getting the right parts from you is too difficult or time-consuming, they are likely to seek aftermarket alternatives that may be easier to obtain.

While aftermarket alternatives may seem appealing for customers, we all know genuine parts ensure quality, safety, and a perfect fit that ultimately lowers the total cost of ownership for your end customers. By streamlining the procurement process, you can maintain your competitive edge and foster long-term customer relationships.

The Call to Action is Clear: Embracing the Future of Spare Parts Management

The call to action is clear: digitalization is the future of a sustainable and profitable spare parts business, and leaders have already taken action.

By embracing digital tools and strategies, you can enhance efficiency, improve customer satisfaction, and drive profitable revenue growth for your business. For those ready to take the next step, we invite you to watch the full webinar on demand and explore how these insights can transform your business.

Our CDS Partable solution is helping leading industrial equipment manufacturers digitize their genuine spare part sales process to drive more revenue and improve customer relations. Whether you are just beginning your digitization journey or accelerating your efforts, CDS has 20+ years of experience and purpose-built solutions to support industrial manufacturers every step of the way.

Whether you are ready to take the first pivotal step into digitizing your genuine parts business or you would like to learn more, contact us for a free consultation.

Back to Blog