CAD (Computer-aided design) has revolutionized the manufacturing landscape.

From its humble beginnings in the 1960s, when Ivan Sutherland of MIT’s Lincoln Laboratory created SKETCHPAD, CAD has evolved into a ubiquitous tool for product design, engineering analysis, and manufacturing. Today, refined CAD software enables engineers to create intricate 2D or 3D models with rich metadata, breathing life into product concepts and facilitating a smooth transition from design through production.

Leaders in industrial manufacturing are finding new ways to utilize their existing CAD assets. CAD’s utility extends far beyond the initial design phase, generating new use cases that improve the experience for everyone involved in the manufacturing process. The wealth of information embedded within these models holds immense potential for downstream applications.

Utilizing your existing CAD files, you can create 2D and 3D visualizations that extend their use cases to drive immersive customer experiences across channels while also enhancing your skilled worker training programs.

Let’s explore how you can leverage your existing CAD assets to deliver powerful 2D and 3D visualizations that support your customer experience and improve several efficiencies.

1. Aftermarket Spare Part Sales:

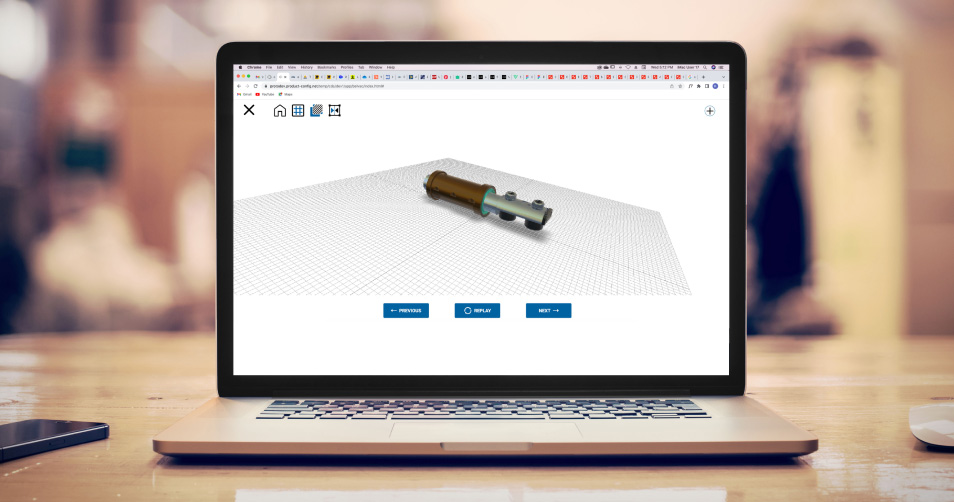

The days of deciphering cryptic part numbers and relying on static catalogs have passed. By leveraging CAD data, you can create interactive 3D visualizations of your spare parts catalog on your website. Imagine customers visiting your website with an e-commerce platform where they can zoom in, rotate, and explore a 3D model to help identify the needed part. Interactive visualization clarifies part identification, reduces errors, and streamlines the ordering process for customers.

Exploding assembly views showcasing part placement within the larger product can be generated from the CAD data, ensuring accuracy that empowers service technicians to quickly identify and locate replacement parts, accelerating repair times and reducing downtime.

Considerations:

- Part explosion: CAD software often offers built-in functionality for creating assembly structures and generating exploded views. Tools like Bill of Materials (BOM) can further streamline the process of delivering 3D parts explosion visualizations.

- Visualization platforms: Choosing a visualization platform that offers user-friendly 3D manipulation tools alongside functionalities like part highlighting and search capabilities is essential. The right platform will ingest your CAD data and give administrators the ability to make adjustments within the aftermarket spare parts search platform.

2. Digital Work Instructions:

Traditional paper-based and PDF work instructions are prone to errors and need more clarity for complex assembly processes. Integrating CAD data into digital work instructions provides a superior alternative. 3D animations showcasing assembly steps, along with highlighted components within the CAD model, offer a step-by-step visual guide for technicians working in the factory or the field. Interactive digital work instructions provide users with an immersive experience that helps improve training quality, safety, and employee satisfaction. Immersive digital work instructions also reduce training times and minimize errors during assembly, leading to improved product quality.

Considerations:

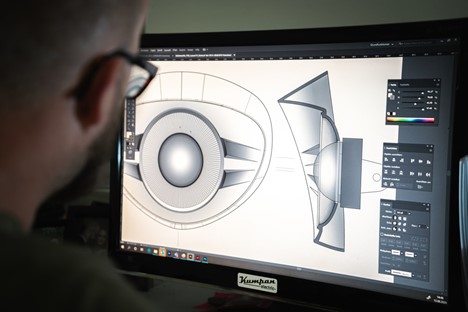

- 2D and 3D Annotation: Tools within CAD software or dedicated animation software can be used to create hotspots, callouts, arrows, and text overlays within the 2D or 3D model, highlighting specific assembly steps.

- Interactivity: Consider platforms that allow various media types and interactive elements to be embedded within the digital work instructions. Users can click on specific components within the 3D model for additional information access, detailed assembly procedures, or engage specifically in blended reality environments.

3. E-commerce for Standard Parts:

For manufacturers with a vast catalog of standard parts, creating individual product images for each item can be time-consuming, expensive, and resource-intensive. By leveraging CAD models, manufacturers can generate high-quality, photorealistic renderings of standard parts. These renderings showcase the part in detail, eliminating the need for physical photography and allowing for quicker updates to product catalogs.

Considerations:

- Rendering Engines: Utilizing advanced rendering engines integrated within CAD software or standalone rendering solutions allows for the creation of hyper-realistic product visualizations. Keep in mind that standalone rendering engines can be great, but it’s another solution to manage.

- Material and Texture Libraries: Access to extensive material and texture libraries within the rendering software helps create product visuals that closely resemble the actual part, enhancing customer perception.

4. Visual Configuration and CAD Automation:

Using visual configuration tools can significantly enhance the customer experience for manufacturers offering customizable products. By integrating CAD data into the configuration engine, customers can virtually assemble their desired product, selecting from various options and instantly visualizing the final configuration in 3D. Additionally, CAD automation solutions empower anyone to generate CAD files for configurable products. Visual Configuration with CAD Automation allows customers to make informed decisions and personalize their purchases, leading to increased customer satisfaction and sales conversions.

Considerations:

- Configuration Engine: It is essential to select a robust configuration engine that seamlessly integrates with CAD data. The engine should allow for defining product variations, constraints between components, and real-time generation of 3D visualizations based on customer selections.

- Data Management: Managing the vast amount of CAD data associated with different product configurations necessitates a well-defined data management strategy. Version control and clear naming conventions are crucial for maintaining data integrity.

By unlocking the hidden potential within existing CAD assets, you can generate powerful 2D and 3D visualizations that support a variety of applications. From enhancing aftermarket part sales and streamlining service operations to empowering customers with visual configuration tools, the possibilities are expansive. As technology continues to evolve, integrating CAD data into these visualization workflows will only become more sophisticated, propelling industrial processes to a new level of efficiency.

Are you curious to see how CDS Visual unlocks your CAD assets to deliver visual experiences? Contact us today!